development of analytical devices for environmental and medical purposes..

development of analytical devices for environmental and medical purposes..The principle of the sensor action is based on measurement of the change of the sensor resistance in atmosphere of the analyzed gas.

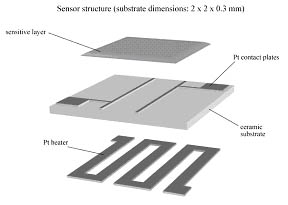

The structure of the sensor is shown schematically in the figure below:

|

The sensor layer is deposited on top of an electrode array printed on a ceramic substrate. The Pt electrodes are connected to the measurement set up which allows collecting data on resistance change. A special snake-shaped resistive resistive heater, made of Pt, is deposited on the bottom side of the substrate. The heater is used to control operation temperature of the sensor to achieve optimal chemical reaction rates. The gas-sensitive layer is based on tin oxide doped with catalytically active additives of transition metals and their oxides. .

Power consumption values of the sensors lie within 0.3 to 0.5 W, depending on gas to be measured. Basic specifications of the sensors are presented in the table:

Power consumption values of the sensors lie within 0.3 to 0.5 W, depending on gas to be measured. Basic specifications of the sensors are presented in the table:

| ¹ ïï | Gas analyzed | Range | Minimal determined concentration | Speed of response | Wattage |

| 1. | methane in air | 0 - 2.5x104 | 1,5 | 3 sec | 0,45 W |

| 2. | propane in air | 0 - 1.5 x104 | 0,5 | 3 sec | 0,45 W |

| 3. | hydrogen in air or inert gases | 0 - 1.5 x104 | 1,0 | 3 sec | 0,45 W |

| 4. | ethanol fumes in breath | 0 - 200 mg/m3 | 3 mg/m3 | 3 sec | 0,35 W |

| 5. | hydrogen sulphide | 0 - 300 mg/m3 | 2 mg/m3 | 3 min | 0,30 W |

| 5. | acetone in breath | 0 - 500 mg/m3 | 5 mg/m3 | 3 sec | 0.40 W |

Sensors possess good sensitivity and response time to H2, small mass and size, and ability to operate in a wide range of ambient temperatures. Sensors consume little energy.

|